|

|

|

|

|

|

|

|

|

|

|

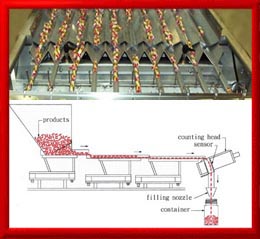

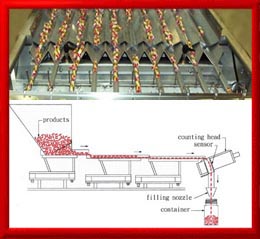

This machine works just like the tablet counter I described in the previous section, except these machines can fill up multiple containers simultaneously at high rates of speed. These machines are very expensive to buy and operate. Usually only the manufacturers or the very largest resellers can afford them because they are very high tech in terms of technology and you need high volumes to recover the capital costs on these machines. The machine you see above is called a Kalish Swift pack. It was purchased at a factory liquidation auction and the brought to Union Standard for storage and resale. The machine was sold to a customer by Union as being in working order and as usually was the case the task fell upon me to figure it all out and make it work again. Thank goodness there was a book and a schematic that came with the machine. Otherwise it would have taken me a long time to get it going. Here is how it works:

A large hopper at the back end is loaded with tablets, pills, or capsules. They come out the bottom and land on a set of vibratory feeder ramps which have multiple lanes on a very gentle and long incline. This machine has 10 lanes and the purpose of these lanes is to allow enough time for the tablet stream to serialize so that they are lined up behind one another just like dominoes all in a row as the end towards the end of the ramp.

Once the pills get to the end of the ramp they start to fall off one by towards the bottle waiting below as they fall they pass through a pencil thin beam of light that extends like a thin plane across the entirety of the sensor hole. As the pills fall through they break the beam and send a count signal to a central processor that is monitoring all ten positions. As the bottles reach their count the feed lane to that bottle is shut down and cutoff until all ten bottles are full.

Finger stopper pistons on the long constantly running conveyor are withdrawn and the 1o bottles are allowed to come and another 10 are brought in and the cycle begins again. The 10 bottles that just left are brought to a casing station down at the other end of the conveyor. The process I described above sounds to be very slow, but it actually takes place at the rate of hundreds of bottles per minute. View the slide show to see and read more about it.